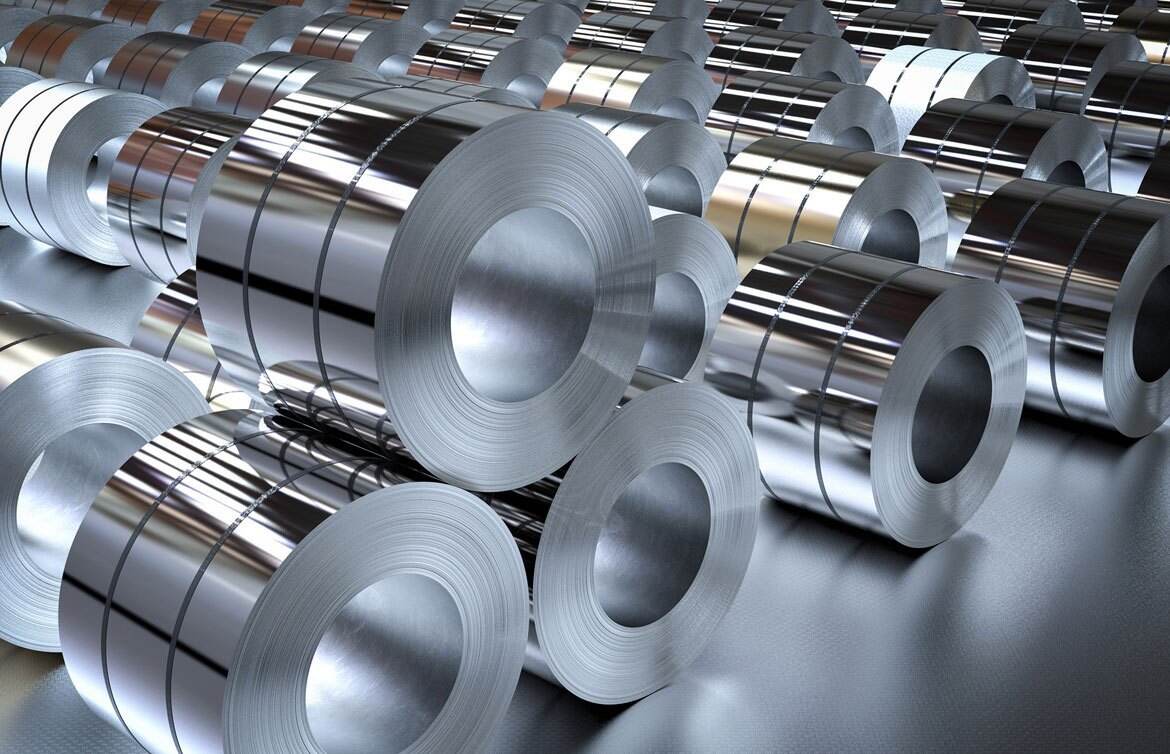

hot rolled black steel

Hot rolled black steel represents a fundamental material in modern manufacturing and construction, produced through a high-temperature rolling process where steel is heated above its recrystallization temperature. This process creates a distinctive black oxide surface, which gives the material its characteristic appearance. The manufacturing process involves heating steel billets to temperatures exceeding 1700°F, followed by processing through a series of rollers that gradually reduce the material's thickness while improving its structural integrity. The resulting product exhibits excellent formability, weldability, and mechanical properties, making it ideal for various industrial applications. The surface texture of hot rolled black steel features a rough, scaly finish that's particularly suitable for applications where appearance is secondary to function. Its versatility extends across multiple sectors, from heavy construction and industrial machinery to automotive components and structural frameworks. The material's cost-effectiveness stems from its straightforward production process, requiring fewer steps than cold-rolled alternatives. Notable characteristics include uniform mechanical properties, good machinability, and the ability to maintain structural integrity under varying temperature conditions. The material's widespread adoption in industrial applications is testament to its reliability and performance capabilities in demanding environments.