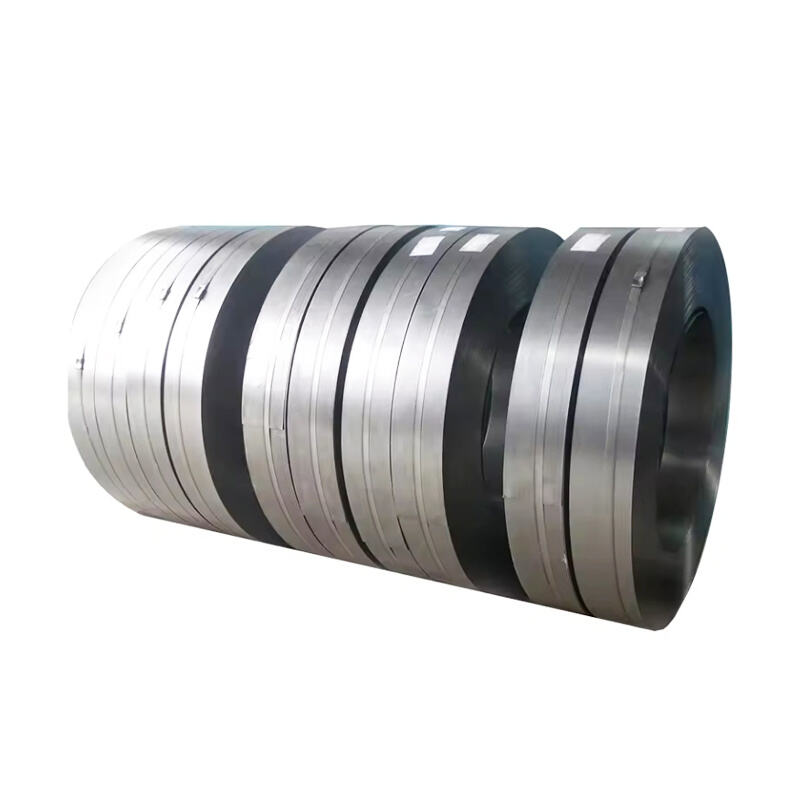

hot rolled carbon steel

Hot rolled carbon steel represents a fundamental material in modern manufacturing and construction, produced through a high-temperature rolling process that shapes steel above its recrystallization temperature. This versatile material is manufactured by heating steel billets to temperatures exceeding 1,700°F, then processing them through a series of rollers to achieve the desired thickness and shape. The process results in a product with consistent mechanical properties throughout its structure. The material exhibits excellent formability, weldability, and machinability, making it ideal for numerous industrial applications. Key characteristics include its high strength-to-weight ratio, good ductility, and cost-effectiveness. Hot rolled carbon steel finds extensive use in structural applications, including beams, channels, and angles for construction projects. It's also commonly utilized in automotive parts, agricultural equipment, industrial machinery, and railway tracks. The material's inherent properties make it particularly suitable for applications requiring strength and durability without necessarily demanding precise tolerances or superior surface finish. The manufacturing process allows for large-scale production, contributing to its economic efficiency and widespread availability in various forms, from plates and sheets to bars and structural sections.