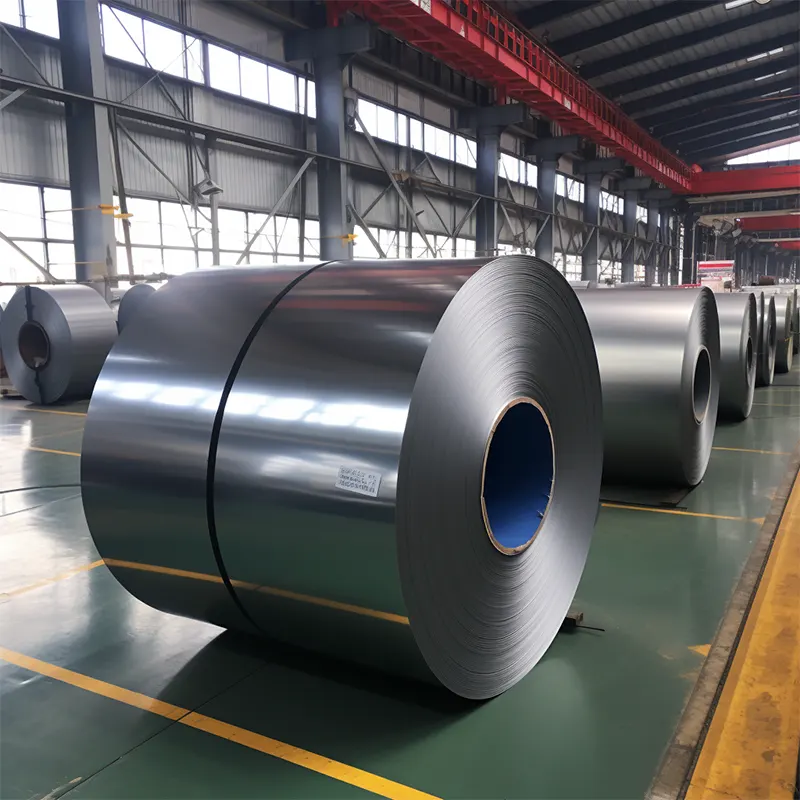

hot rolled products

Hot rolled products represent a fundamental cornerstone in the metal manufacturing industry, created through a sophisticated metallurgical process where metal is heated above its recrystallization temperature and passed through multiple rolls. This process yields materials with distinctive characteristics, including enhanced strength, improved formability, and consistent dimensional accuracy. The manufacturing process typically begins with heating metal billets or slabs to temperatures exceeding 1,700°F, followed by progressive rolling and controlled cooling. These products are extensively utilized across various sectors, from construction and automotive to infrastructure development. The resulting materials feature a characteristic surface finish with slight scaling and less precise tolerances compared to cold rolled products, making them ideal for applications where exact dimensions are less critical. Hot rolled products are available in various forms, including sheets, plates, bars, and structural shapes, each serving specific industrial needs. The process's efficiency and cost-effectiveness make it particularly suitable for large-scale manufacturing, while the material's enhanced ductility facilitates easier forming and shaping operations.