low silicon steel

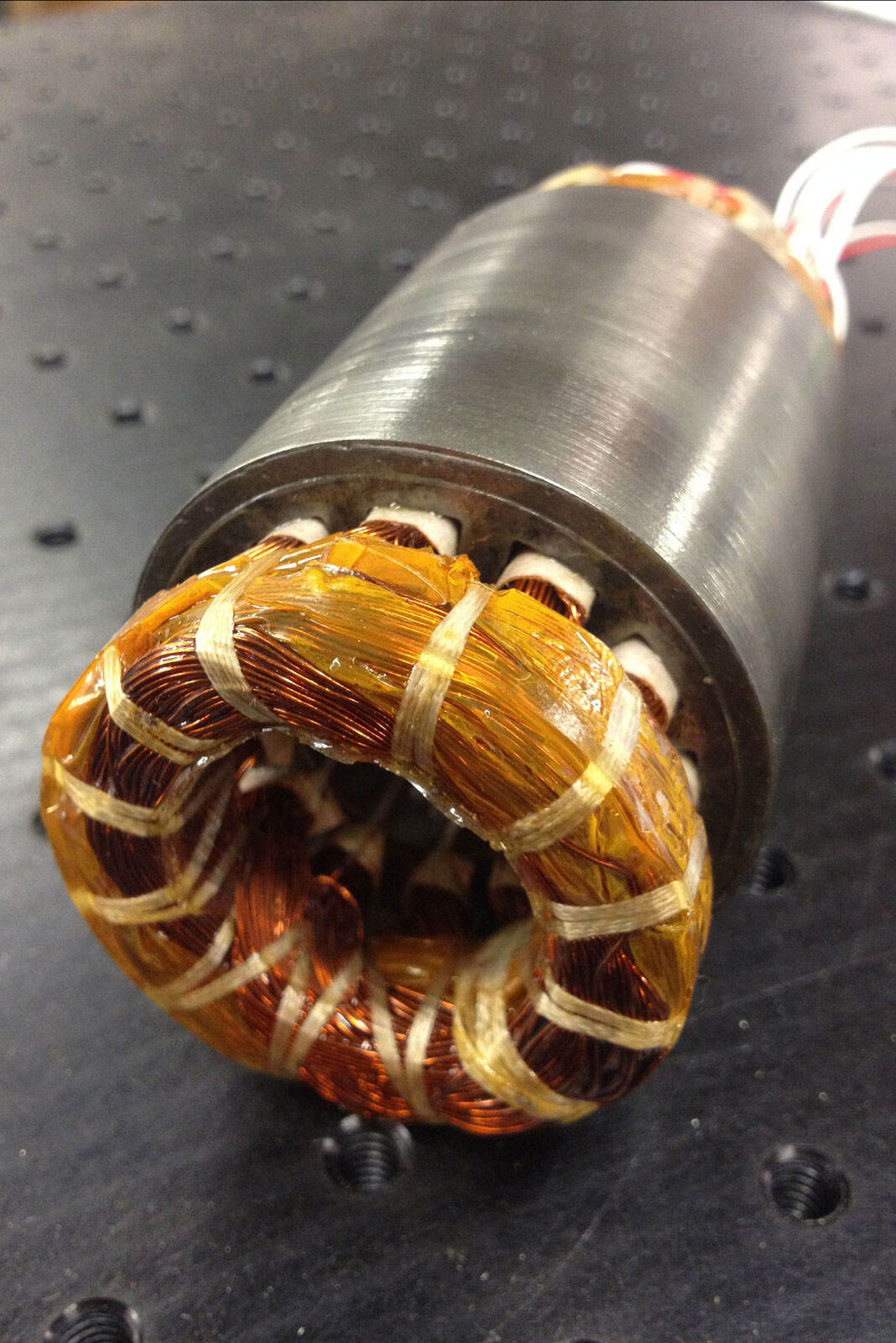

Low silicon steel, also known as electrical steel or silicon steel with low silicon content, represents a specialized magnetic material engineered for optimal electromagnetic performance. This material typically contains silicon content ranging from 0.5% to 2.5%, carefully balanced to achieve specific magnetic and mechanical properties. The controlled silicon content helps reduce core losses while maintaining excellent magnetic permeability, making it ideal for various electrical applications. The material's crystal structure is specifically oriented to enhance magnetic flux density and minimize energy losses during magnetization cycles. Low silicon steel exhibits superior magnetic properties, including high magnetic saturation and low coercivity, which are essential for efficient energy conversion in electrical equipment. The material undergoes precise manufacturing processes, including cold rolling and specialized heat treatments, to achieve the desired grain orientation and magnetic characteristics. Its versatility makes it invaluable in applications ranging from small motors and generators to large power transformers. The material's mechanical properties, including good ductility and machinability, facilitate easy fabrication and assembly in manufacturing processes, while its relatively low cost compared to higher silicon variants makes it economically viable for large-scale industrial applications.