prepainted galvanized steel sheet

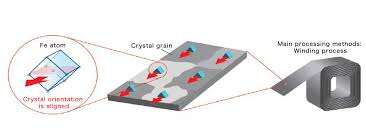

Prepainted galvanized steel sheet represents a sophisticated combination of durability and aesthetic appeal in modern construction materials. This innovative product consists of a steel core that undergoes hot-dip galvanization, followed by a specialized paint coating process. The galvanization process creates a protective zinc layer that shields the steel from corrosion, while the paint coating adds both visual appeal and additional protection. These sheets are manufactured through a continuous coating line where the steel is cleaned, treated, and coated under strictly controlled conditions to ensure optimal adhesion and uniformity. The material's versatility makes it ideal for various applications, including roofing systems, wall cladding, automotive components, and appliance manufacturing. The paint coating is typically composed of multiple layers, including primers and top coats, each serving specific functions such as adhesion promotion, corrosion resistance, and UV protection. Available in an extensive range of colors and finishes, prepainted galvanized steel sheets can be customized to meet specific project requirements while maintaining their structural integrity and protective properties.