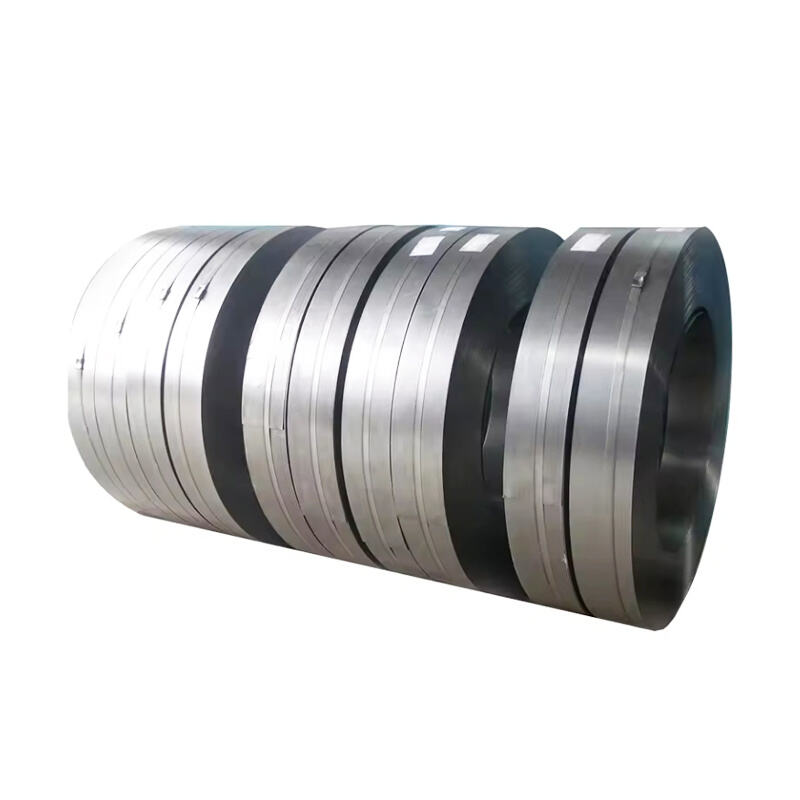

electrical steel manufacturer

An electrical steel manufacturer specializes in producing high-quality silicon steel materials essential for power generation and distribution equipment. These manufacturers employ advanced metallurgical processes to create specialized steel grades with optimized magnetic properties, crucial for transformers, motors, and generators. The manufacturing process involves precise control of silicon content, grain orientation, and surface coating applications to achieve specific magnetic permeability and core loss characteristics. Modern electrical steel production facilities utilize state-of-the-art technology, including continuous annealing lines, precision coating systems, and automated quality control measures. These manufacturers offer both grain-oriented and non-oriented electrical steel varieties, each engineered for specific applications. The production process ensures consistent material properties, meeting international standards for electrical steel quality. Advanced facilities maintain strict environmental controls and energy efficiency measures while implementing smart manufacturing principles to optimize production. These manufacturers also provide technical support and customization options to meet specific customer requirements, ensuring optimal performance in various electrical applications.