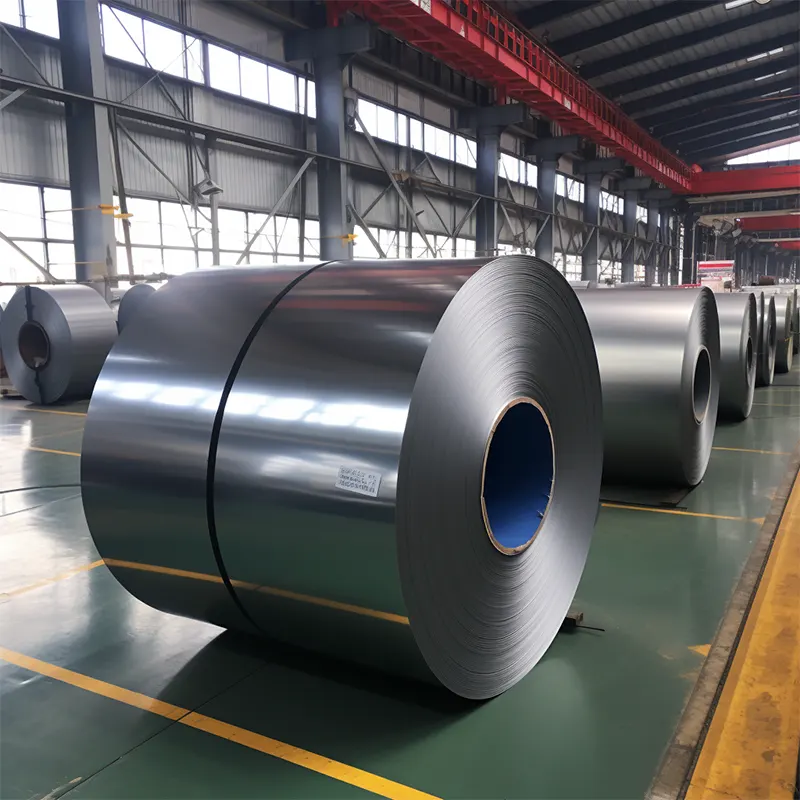

electrical steel manufacturers

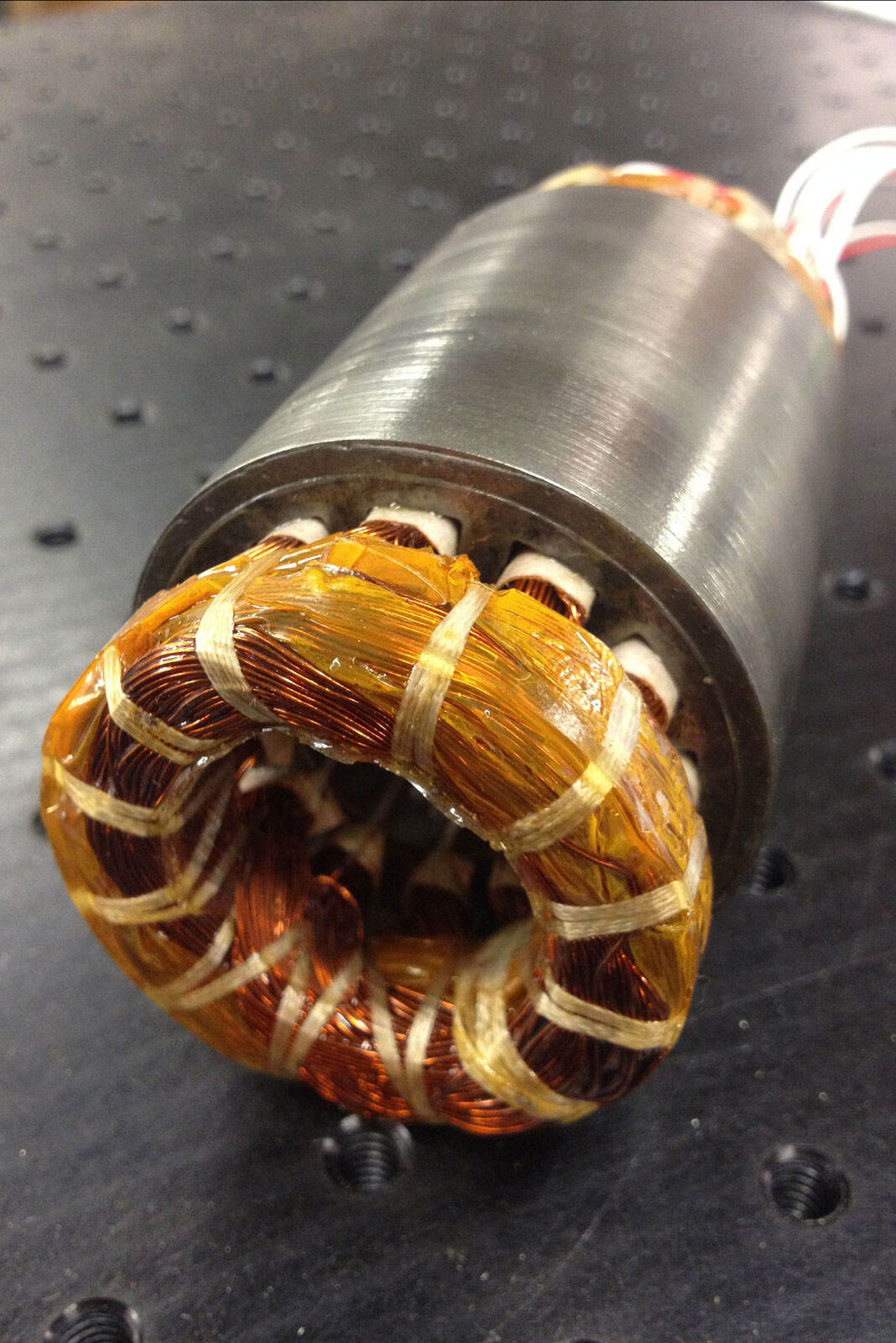

Electrical steel manufacturers are specialized industrial enterprises that produce essential materials for the power and electronics sectors. These manufacturers create highly specialized silicon steel products, also known as electrical steel or transformer steel, which are engineered specifically for electromagnetic applications. The manufacturing process involves sophisticated metallurgical techniques to produce steel with specific magnetic properties, including high permeability and low core loss. These manufacturers utilize advanced production technologies, including precise cold rolling processes, specialized heat treatments, and surface insulation applications. Their products are fundamental components in transformers, motors, generators, and other electromagnetic devices. The facilities typically maintain strict quality control measures and adhere to international standards to ensure consistent product performance. Modern electrical steel manufacturers employ cutting-edge automation systems and quality testing equipment to monitor and control the production process, ensuring optimal magnetic properties and mechanical characteristics. They often offer various grades of electrical steel, from standard grades for common applications to high-performance varieties for specialized uses. These manufacturers also provide technical support and customization options to meet specific customer requirements, making them crucial partners in the electrical and electronics manufacturing supply chain.