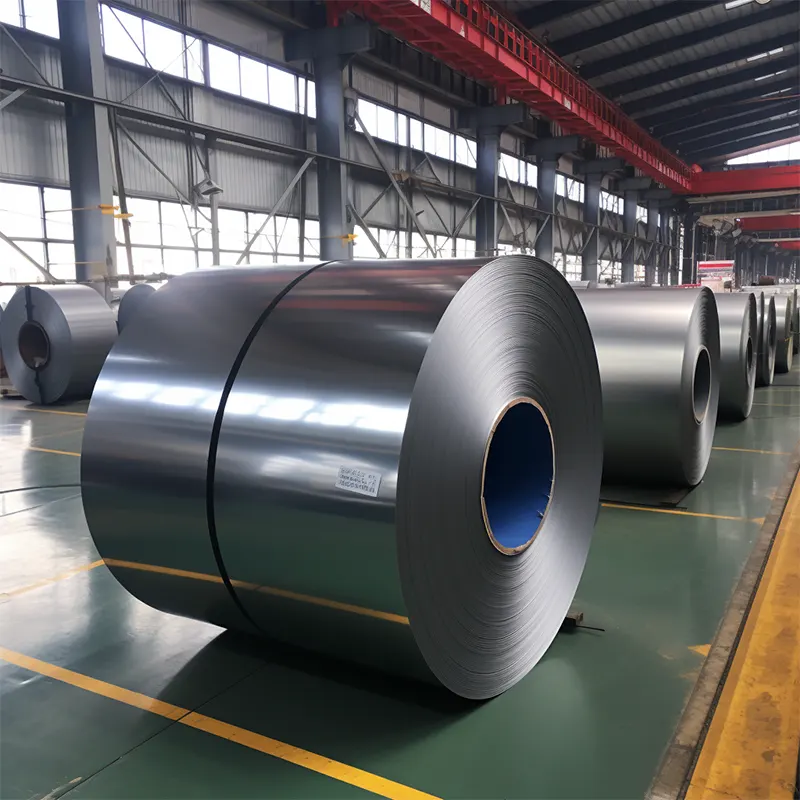

cold rolled silicon steel

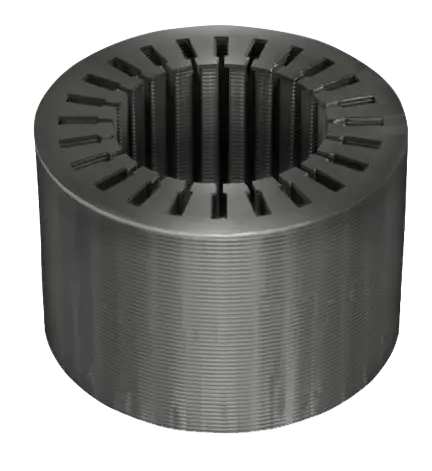

Cold rolled silicon steel represents a specialized electrical steel product engineered for exceptional magnetic properties and performance. This material undergoes a precise cold rolling process that significantly enhances its grain orientation and magnetic characteristics. The steel contains specific percentages of silicon, typically ranging from 2% to 6.5%, which helps reduce energy losses and improve magnetic permeability. The manufacturing process involves careful control of temperature, pressure, and rolling direction to achieve optimal grain orientation, resulting in superior magnetic properties along the rolling direction. Cold rolled silicon steel is distinguished by its low core loss, high magnetic permeability, and excellent magnetic flux density. These properties make it indispensable in the production of various electrical equipment, particularly transformers, motors, and generators. The material's unique crystallographic texture allows for efficient magnetic domain alignment, minimizing energy losses during magnetization cycles. Its controlled thickness tolerance and superior surface finish ensure consistent performance in electrical applications. Modern production techniques have enabled manufacturers to achieve increasingly thin gauges while maintaining excellent magnetic properties, contributing to more efficient and compact electrical devices.