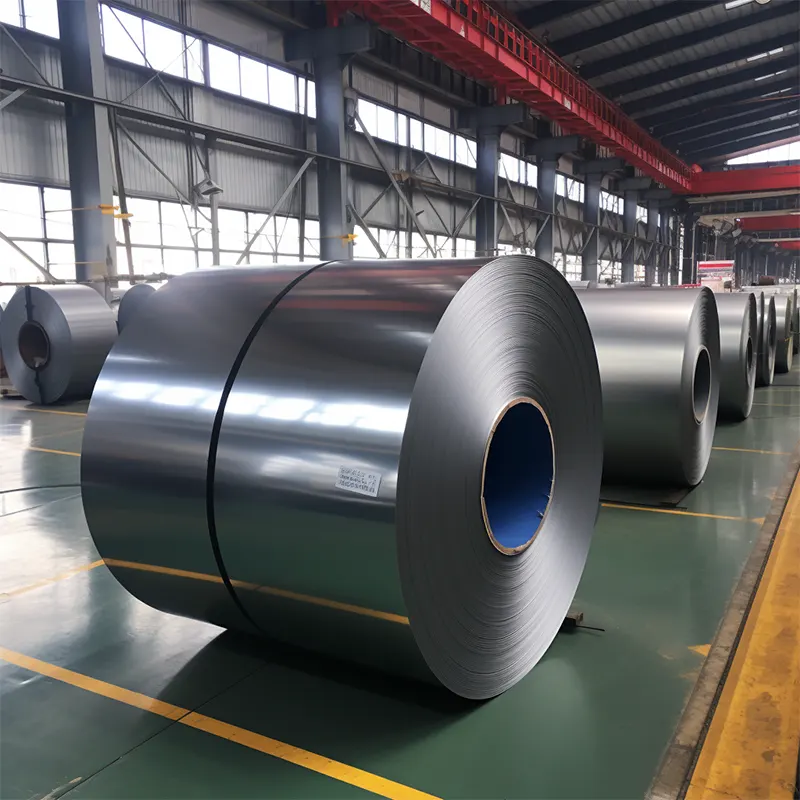

galvanized steel coil manufacturers

Galvanized steel coil manufacturers represent the backbone of modern industrial metal processing, specializing in producing high-quality zinc-coated steel products that offer superior corrosion resistance and durability. These manufacturers employ advanced hot-dip galvanization processes, where steel sheets are immersed in molten zinc at temperatures around 860°F (460°C). This process creates a metallurgically bonded zinc coating that protects the underlying steel from oxidation and rust. Leading manufacturers utilize state-of-the-art continuous galvanizing lines equipped with precise thickness control systems and automated quality inspection technologies. These facilities can produce coils in various specifications, including different zinc coating weights, surface finishes, and mechanical properties. The manufacturing process incorporates rigorous quality control measures, from raw material selection to final product testing, ensuring consistent product quality and meeting international standards such as ASTM and EN. Modern manufacturers also implement environmentally conscious practices, including zinc recovery systems and energy-efficient production methods, while maintaining high production capacities to meet global demand across construction, automotive, and infrastructure sectors.