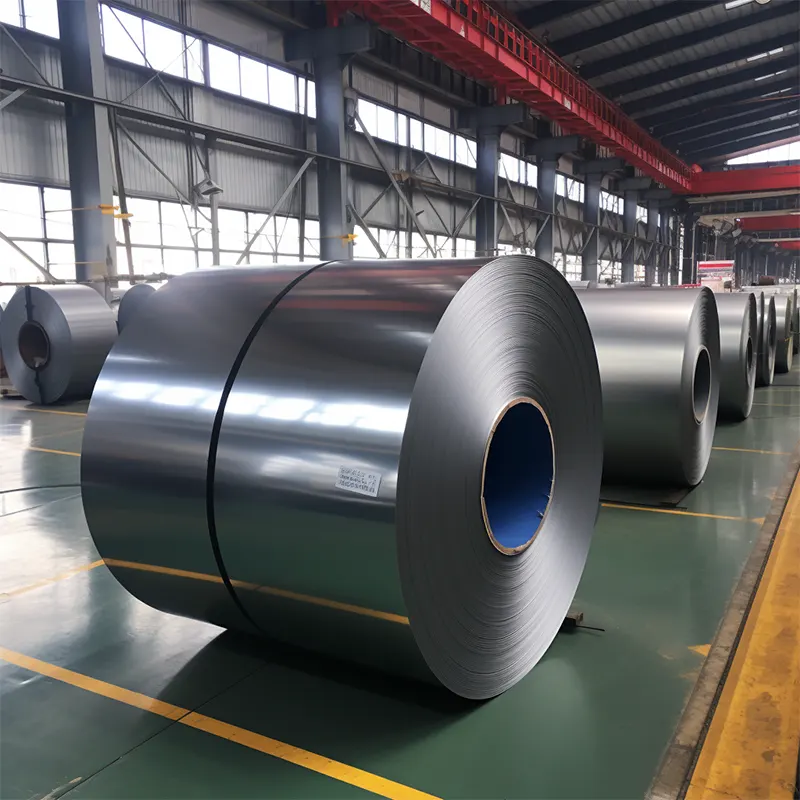

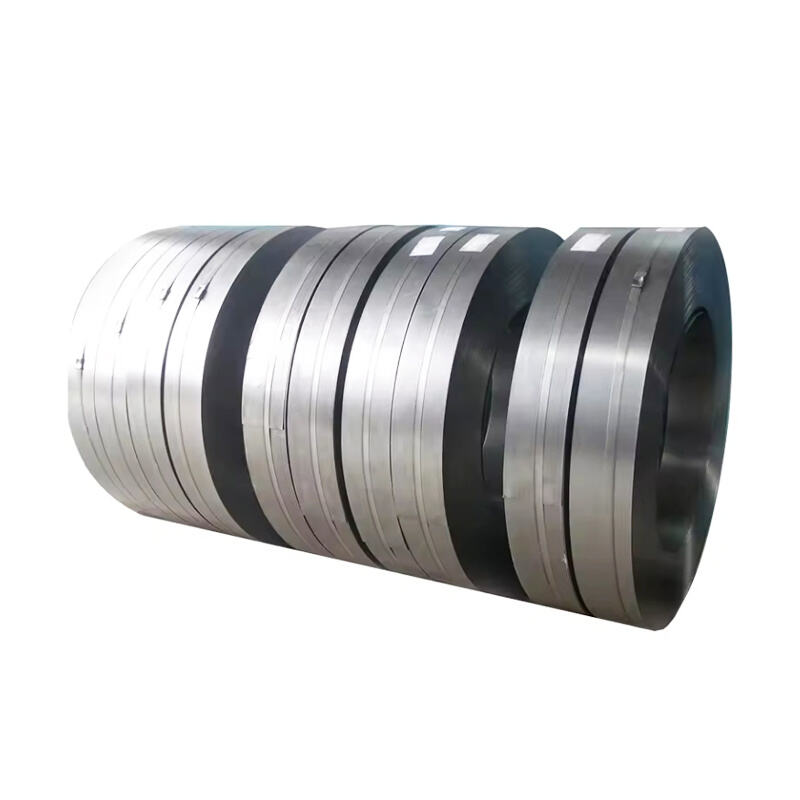

spcc cold rolled steel sheet

SPCC cold rolled steel sheet represents a premium grade steel product manufactured through an advanced cold rolling process. This specialized manufacturing method involves reducing the thickness of hot rolled steel by passing it through rollers at room temperature, resulting in superior surface finish and enhanced mechanical properties. The process significantly improves the steel's dimensional accuracy, surface smoothness, and overall strength characteristics. SPCC grade specifically denotes a commercial quality cold rolled steel that offers excellent formability and weldability. The material features consistent thickness throughout, typically ranging from 0.15mm to 3.0mm, with precise tolerances. The surface quality is notably superior, presenting minimal imperfections and a smooth finish that makes it ideal for various applications requiring aesthetic appeal. The steel's chemical composition is carefully controlled to ensure optimal performance, featuring low carbon content that contributes to its excellent workability. This material demonstrates remarkable flatness and uniformity, crucial for manufacturing processes that demand high precision and reliability.