spcc steel

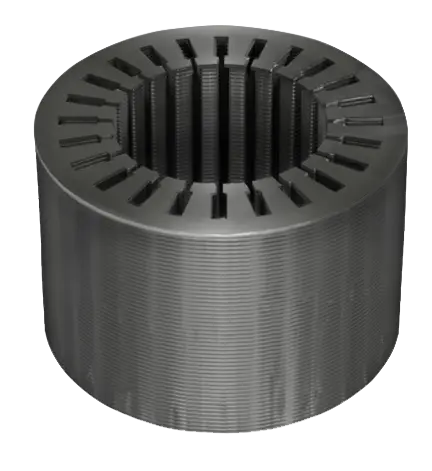

SPCC steel, a cold-rolled mild steel product, stands as a versatile and widely used material in various industrial applications. This steel grade is manufactured through a precise cold-rolling process that enhances its surface finish and dimensional accuracy. The material features excellent formability, making it ideal for deep drawing and bending operations. SPCC steel typically contains low carbon content, usually less than 0.15%, which contributes to its superior malleability and workability characteristics. The steel undergoes careful processing to achieve uniform thickness distribution and superior surface quality, making it particularly suitable for applications requiring aesthetic appeal. Its mechanical properties include moderate tensile strength, typically ranging from 270 to 370 MPa, and good elongation capabilities, usually between 30% to 40%. These characteristics make SPCC steel an optimal choice for various manufacturing processes, including stamping, bending, and forming operations. The material's consistency in quality and performance has established it as a standard in industries such as automotive parts manufacturing, electrical appliances, and general engineering applications.