The selection of appropriate materials for manufacturing household appliances has become increasingly critical as consumers demand both durability and cost-effectiveness. Home appliance steel represents one of the most significant material choices that manufacturers face when designing products ranging from refrigerators and washing machines to ovens and dishwashers. Understanding the intricate balance between price and quality in home appliance steel selection can help both manufacturers and consumers make informed decisions that deliver long-term value. The steel grade, thickness, coating, and processing methods all contribute to the final cost structure while directly impacting the appliance's performance, longevity, and aesthetic appeal.

Understanding Steel Grades and Their Impact on Cost

Carbon Steel Variations in Appliance Manufacturing

Carbon steel remains the foundation material for many appliances due to its versatility and relatively low cost. Low-carbon steel grades, typically containing less than 0.3% carbon, offer excellent formability and weldability, making them ideal for appliance housings and internal components. These grades provide adequate strength for most applications while maintaining cost-effectiveness. Medium-carbon steels, with carbon content between 0.3% and 0.6%, offer enhanced strength and durability but come at a higher price point. The selection between these grades often depends on the specific stress requirements of the appliance component and the target market positioning.

The processing costs associated with different carbon steel grades can vary significantly based on the required heat treatment and forming operations. Lower carbon content generally translates to easier machining and forming processes, reducing manufacturing costs. However, applications requiring higher strength may necessitate medium-carbon grades despite the increased material and processing expenses. Manufacturers must carefully evaluate the trade-off between initial material costs and long-term performance benefits when selecting carbon steel grades for their home appliance steel applications.

Stainless Steel Premium Options

Stainless steel represents the premium tier of home appliance steel options, offering superior corrosion resistance, aesthetic appeal, and durability. The most common grades used in appliances include 304 and 430 stainless steel, each with distinct cost-benefit profiles. Grade 304 stainless steel, containing chromium and nickel, provides excellent corrosion resistance and maintains its appearance over extended periods. This grade typically costs 3-4 times more than carbon steel but offers significant advantages in terms of hygiene, cleaning ease, and visual appeal.

Grade 430 stainless steel, which contains chromium but no nickel, offers a more cost-effective alternative while still providing good corrosion resistance. This grade is magnetic, unlike 304 stainless steel, and finds applications in appliance components where moderate corrosion resistance is sufficient. The price differential between 430 and 304 grades can be substantial, making 430 an attractive option for manufacturers seeking to offer stainless steel aesthetics at a more accessible price point. The selection between these grades often depends on the specific environment in which the appliance will operate and the target consumer segment.

Coating Technologies and Their Economic Implications

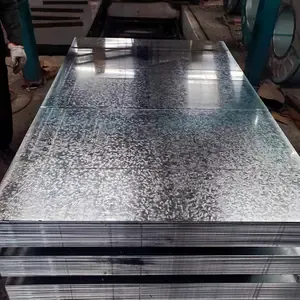

Galvanized Steel Solutions

Galvanized coating represents one of the most cost-effective methods for enhancing the corrosion resistance of home appliance steel without the premium cost of stainless steel. Hot-dip galvanizing provides a thick, durable zinc coating that effectively protects the underlying steel from rust and corrosion. This process typically adds 10-15% to the base steel cost while providing significantly improved durability compared to uncoated carbon steel. The galvanized coating also offers excellent paintability, allowing manufacturers to apply decorative finishes over the protective zinc layer.

Electrogalvanized steel offers a thinner, more uniform coating compared to hot-dip galvanizing, making it suitable for applications requiring precise dimensional tolerances. While the coating thickness is reduced, the process provides better surface finish quality and improved formability. The cost premium for electrogalvanized steel is typically lower than hot-dip galvanizing, making it an attractive option for components that require moderate corrosion protection without the expense of thicker coatings. The choice between galvanizing methods often depends on the specific performance requirements and the manufacturing processes involved.

Advanced Coating Systems

Modern appliance manufacturers increasingly utilize advanced coating systems that combine multiple protective layers to optimize both performance and cost. Zinc-aluminum-magnesium coatings provide superior corrosion resistance compared to traditional galvanizing while maintaining reasonable cost structures. These advanced coatings can extend appliance life significantly, justifying their higher initial cost through reduced warranty claims and improved customer satisfaction. The application of these coatings requires specialized equipment and processes, contributing to higher manufacturing costs but delivering enhanced product value.

Organic coatings applied over metallic substrates offer additional protection and aesthetic options for home appliance steel applications. These systems typically involve a primer coat followed by a topcoat, each designed for specific performance characteristics. While the coating process adds complexity and cost to manufacturing, the resulting products often command premium pricing in the marketplace. The durability and appearance retention of these advanced coating systems can significantly impact the total cost of ownership for consumers, making them valuable despite higher initial costs.

Thickness Considerations and Economic Trade-offs

Standard Gauge Applications

The thickness of home appliance steel directly impacts both material costs and performance characteristics. Standard gauge selections for appliance applications typically range from 22 gauge (0.8mm) for internal components to 16 gauge (1.6mm) for structural elements. Thinner gauges offer material cost savings but may require additional reinforcement or design modifications to achieve required strength and rigidity. The selection of appropriate thickness involves balancing material costs against manufacturing complexity and performance requirements.

Cost optimization often drives manufacturers toward the thinnest gauge that meets performance specifications, as steel costs scale directly with thickness. However, excessively thin materials can lead to manufacturing challenges, including increased forming complexity, higher rejection rates, and potential quality issues. The economic optimum typically involves selecting the minimum thickness that ensures reliable manufacturing while meeting all performance requirements. This approach minimizes material costs while avoiding the hidden costs associated with manufacturing difficulties and quality problems.

Heavy Gauge Requirements

Certain appliance applications require heavier gauge steel to meet structural or safety requirements, despite the associated cost increases. Load-bearing components, pressure vessels, and high-stress areas often necessitate thicker materials to ensure safe operation throughout the appliance's service life. The cost impact of heavy gauge steel extends beyond material expenses to include increased shipping costs, more powerful forming equipment requirements, and potentially modified manufacturing processes.

The selection of heavy gauge home appliance steel often represents a critical design decision that balances safety, performance, and cost considerations. While the material cost premium for thicker gauges is substantial, the enhanced durability and safety margins can justify the expense through reduced liability exposure and improved product reputation. Manufacturers must carefully evaluate the long-term implications of gauge selection, considering not only immediate material costs but also manufacturing efficiency, product performance, and market positioning.

Manufacturing Process Impact on Total Cost

Forming and Fabrication Considerations

The manufacturing processes required for different types of home appliance steel significantly influence the total production cost beyond the raw material expense. Cold-rolled steel, while more expensive than hot-rolled alternatives, often provides superior surface finish and dimensional accuracy that can reduce subsequent processing requirements. The improved formability of cold-rolled steel can lead to fewer manufacturing defects and higher production yields, potentially offsetting the higher material cost through improved manufacturing efficiency.

Deep drawing operations, common in appliance manufacturing, require steel with specific mechanical properties to avoid cracking or wrinkling during forming. Steels optimized for deep drawing applications typically command premium pricing but enable the production of complex shapes in single operations. This capability can eliminate the need for multiple forming steps or secondary operations, reducing labor costs and improving production efficiency. The economic benefit of using specialized forming grades often justifies their higher cost through reduced manufacturing complexity and improved quality.

Welding and Assembly Factors

The weldability characteristics of different steel grades directly impact assembly costs and production efficiency in appliance manufacturing. Low-carbon steels generally offer excellent weldability with minimal preheating requirements, enabling high-speed production processes. Higher carbon content or alloying elements can complicate welding operations, requiring specialized procedures, consumables, or post-weld treatments that increase manufacturing costs. The selection of steel grades must consider not only the material cost but also the impact on assembly operations and quality requirements.

Automated welding processes, increasingly common in appliance manufacturing, require consistent material properties to maintain quality and productivity. Steel grades with tight compositional tolerances and predictable mechanical properties enable reliable automated joining processes, reducing labor costs and improving consistency. While these specialized grades may carry premium pricing, their contribution to manufacturing efficiency and quality often provides net cost benefits. The total cost analysis must encompass both material expenses and the broader impact on production systems and quality outcomes.

Market Dynamics and Price Volatility

Global Steel Market Influences

The pricing of home appliance steel is subject to significant volatility driven by global market conditions, raw material availability, and economic factors. Iron ore and coking coal prices, the primary inputs for steel production, can fluctuate dramatically based on supply disruptions, demand variations, and geopolitical events. These fluctuations directly impact steel pricing, creating challenges for appliance manufacturers in maintaining consistent product costs and profit margins. Understanding these market dynamics is essential for making informed material selection decisions and developing effective procurement strategies.

Currency exchange rates add another layer of complexity to steel pricing, particularly for manufacturers sourcing materials internationally or competing in global markets. A weakening domestic currency can significantly increase the cost of imported steel or raw materials, forcing manufacturers to evaluate domestic alternatives or adjust pricing strategies. Long-term contracts and hedging strategies can help mitigate some price volatility, but these risk management tools typically involve additional costs that must be factored into the overall economic analysis.

Supply Chain Considerations

The selection of steel suppliers and the structure of supply relationships significantly influence both cost and quality outcomes for appliance manufacturers. Local suppliers may offer price advantages through reduced transportation costs and shorter lead times, but may have limited capacity or capability compared to larger regional or international suppliers. The evaluation of supplier options must consider not only unit pricing but also reliability, quality consistency, technical support, and financial stability.

Just-in-time manufacturing strategies, while reducing inventory carrying costs, can increase vulnerability to supply disruptions and price volatility. Maintaining strategic inventory levels or developing multiple supply sources can provide price stability and supply security but requires additional working capital and storage facilities. The optimal supply chain strategy balances cost minimization with risk management, considering the specific requirements and constraints of each manufacturing operation.

Quality Assessment and Performance Metrics

Durability and Longevity Factors

The long-term performance of home appliance steel directly influences customer satisfaction, warranty costs, and brand reputation, making quality assessment a critical component of material selection decisions. Corrosion resistance testing, including salt spray and cyclic corrosion tests, provides quantitative measures of material durability under various environmental conditions. These test results help predict service life and maintenance requirements, enabling more accurate total cost of ownership calculations for both manufacturers and consumers.

Mechanical property testing, including tensile strength, yield strength, and fatigue resistance, ensures that selected materials will withstand the operational stresses encountered in appliance service. Higher-quality steels typically demonstrate superior mechanical properties, translating to longer service life and reduced failure rates. While premium materials require higher initial investment, the reduced warranty costs and improved customer satisfaction often justify the expense through enhanced profitability and market positioning.

Surface Quality and Aesthetic Performance

The surface quality of home appliance steel significantly impacts both manufacturing efficiency and final product appearance. Premium surface finishes reduce the need for extensive preparation before coating or finishing operations, potentially offsetting higher material costs through reduced processing requirements. Consistent surface quality also improves coating adhesion and appearance, contributing to better product aesthetics and durability.

Defect-free surfaces minimize rejection rates during manufacturing and reduce the need for rework or repair operations. While premium surface grades command higher pricing, their contribution to manufacturing efficiency and product quality often provides net cost benefits. The evaluation of surface quality must consider both immediate manufacturing implications and long-term performance in service, including appearance retention and maintenance requirements.

FAQ

What factors most significantly influence the cost of home appliance steel

The primary cost drivers for home appliance steel include the base steel grade, coating type and thickness, material gauge, and current market conditions. Stainless steel grades typically cost 3-4 times more than carbon steel, while advanced coatings can add 15-25% to base material costs. Market volatility in raw materials like iron ore and energy costs can cause price fluctuations of 20-30% over short periods. Manufacturing volume and supplier relationships also significantly impact final pricing, with larger orders typically receiving better unit rates.

How do different steel grades impact appliance performance and longevity

Higher-grade steels generally provide superior corrosion resistance, strength, and durability, directly impacting appliance service life. Stainless steel applications can last 15-20 years with minimal maintenance, while coated carbon steels typically provide 10-15 years of reliable service. Premium steel grades also maintain their appearance better over time, reducing the need for refinishing or replacement. The choice of steel grade should align with the intended service environment and expected product lifespan to optimize value.

What coating options provide the best balance of cost and protection

Galvanized coatings offer excellent cost-effectiveness for most appliance applications, providing 10-15 years of corrosion protection at a 10-15% cost premium over bare steel. Zinc-aluminum-magnesium coatings provide superior protection for demanding environments at moderate cost increases. For premium applications, organic coating systems over metallic substrates deliver exceptional durability and appearance retention, justifying their higher cost through extended service life and reduced maintenance requirements.

How can manufacturers optimize steel selection for different market segments

Market segmentation strategies should align steel selection with target customer expectations and price points. Entry-level products can utilize galvanized carbon steel to minimize costs while providing adequate performance. Mid-market appliances benefit from premium coated steels that offer enhanced durability and appearance. Luxury segments justify stainless steel or advanced coating systems through superior performance, aesthetics, and longevity. The key is matching material costs with market positioning to optimize both competitiveness and profitability.