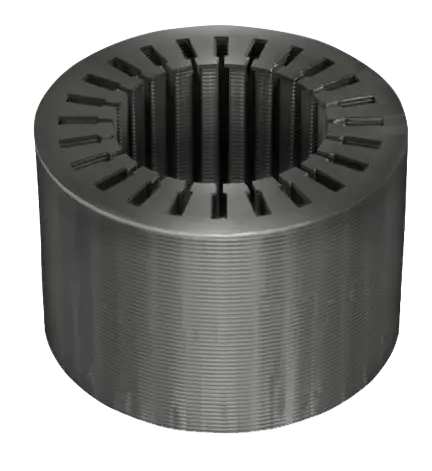

silicon steel laminations

Silicon steel laminations are essential components in electrical and electromagnetic applications, serving as the core material in transformers, motors, and generators. These specialized steel sheets are manufactured with precise silicon content, typically ranging from 2% to 6.5%, which enhances their magnetic properties while reducing energy losses. The laminations are thin layers of silicon-alloyed steel that are stacked together and insulated from each other to minimize eddy current losses. This strategic design allows for efficient magnetic flux conduction while maintaining low core losses. The manufacturing process involves careful control of grain orientation, thickness, and surface coating to achieve optimal electromagnetic performance. Silicon steel laminations are characterized by their high magnetic permeability, low hysteresis loss, and excellent core loss characteristics. These properties make them indispensable in various industrial applications where electromagnetic efficiency is crucial. The laminations can be produced in different grades and thicknesses to meet specific application requirements, from high-frequency transformers to large power distribution systems.