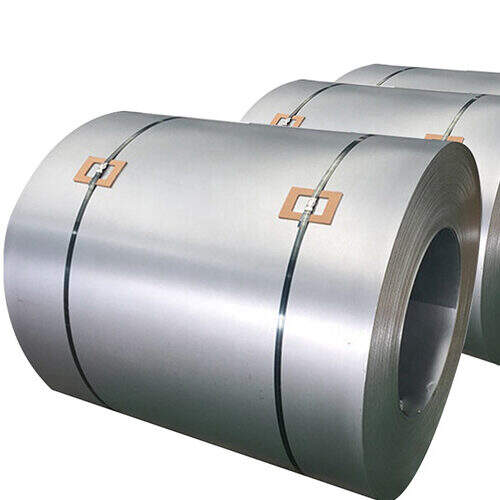

zinc galvanized steel

Zinc galvanized steel represents a revolutionary advancement in metal protection technology, combining the structural strength of steel with the corrosion-resistant properties of zinc. This innovative material is created through a specialized hot-dip galvanization process, where steel is immersed in molten zinc at temperatures around 860°F (460°C). During this process, the zinc chemically bonds with the steel surface, forming multiple metallurgical layers that provide exceptional protection against corrosion and environmental damage. The resulting coating consists of various zinc-iron alloy layers, crowned by a pure zinc outer layer, creating a comprehensive shield that offers both barrier and sacrificial protection. The galvanized coating naturally develops a protective patina of zinc carbonate when exposed to the atmosphere, which further enhances its durability and longevity. This material has become indispensable in various industries, from construction and automotive to infrastructure and utilities, owing to its remarkable combination of strength, durability, and cost-effectiveness. The versatility of zinc galvanized steel makes it suitable for applications ranging from structural components and roofing materials to highway guardrails and utility poles, providing reliable performance in diverse environmental conditions.