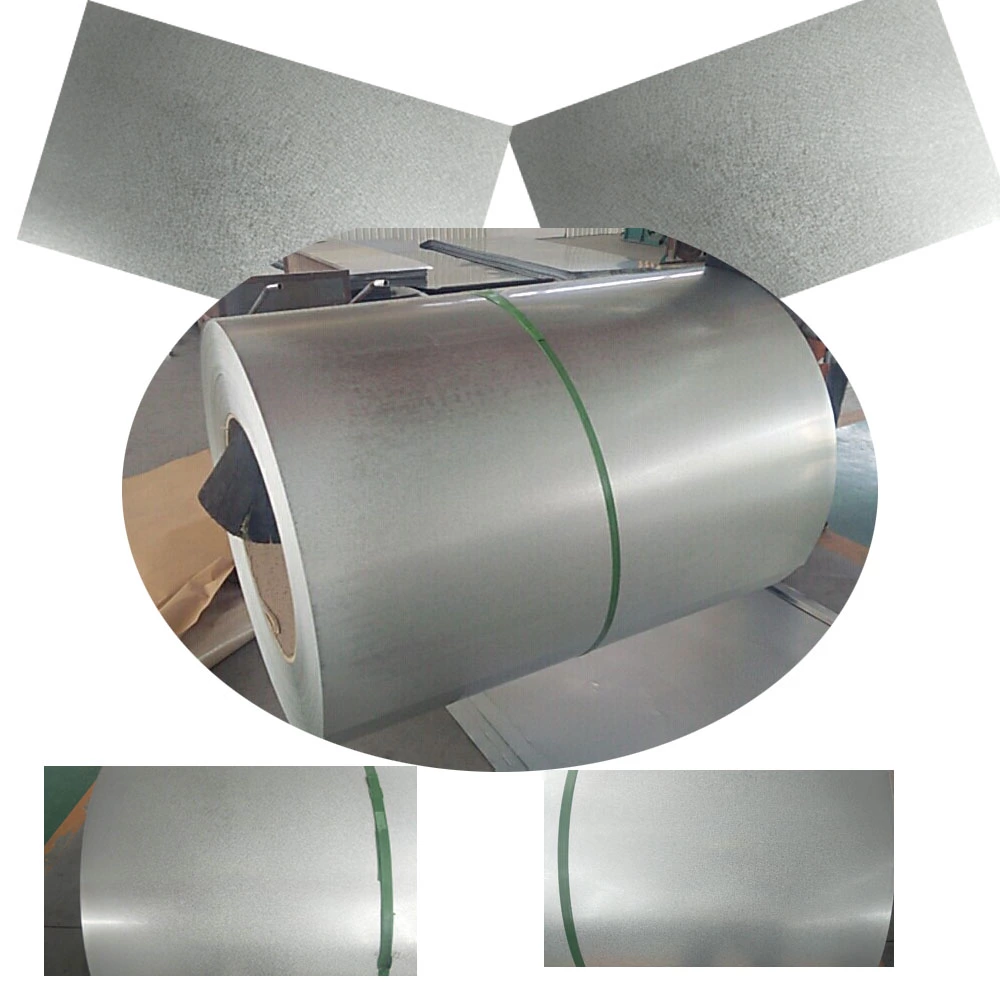

оцинкованное погружение

Горячее цинкование — это сложный процесс металлического покрытия, который обеспечивает исключительную защиту от коррозии путем погружения стальных или чугунных компонентов в расплавленный цинк. Этот процесс, протекающий приблизительно при 840°F (449°C), создает металлургически связанное покрытие, состоящее из нескольких слоев цинково-железных сплавов, поверх которых находится внешний слой чистого цинка. Получаемое покрытие обеспечивает превосходную защиту от ржавчины и коррозии, срок службы которого обычно составляет 50 лет и более во многих условиях эксплуатации. В ходе процесса расплавленный цинк вступает в реакцию с поверхностью стали, образуя ряд слоев цинково-железного сплава, которые по своей твердости даже превосходят основную сталь. Это создает прочный защитный барьер, который не только защищает металл от коррозионных воздействий, но также обеспечивает механическую защиту от ударов и абразивного износа. Покрытие проникает на все поверхности, включая труднодоступные места, гарантируя полное покрытие даже в сложных геометрических конфигурациях. Такая всесторонняя защита делает горячее цинкование особенно ценным для применения в строительных стальных конструкциях, наружном оборудовании и в морских условиях, где постоянно присутствуют агрессивные воздействия окружающей среды.