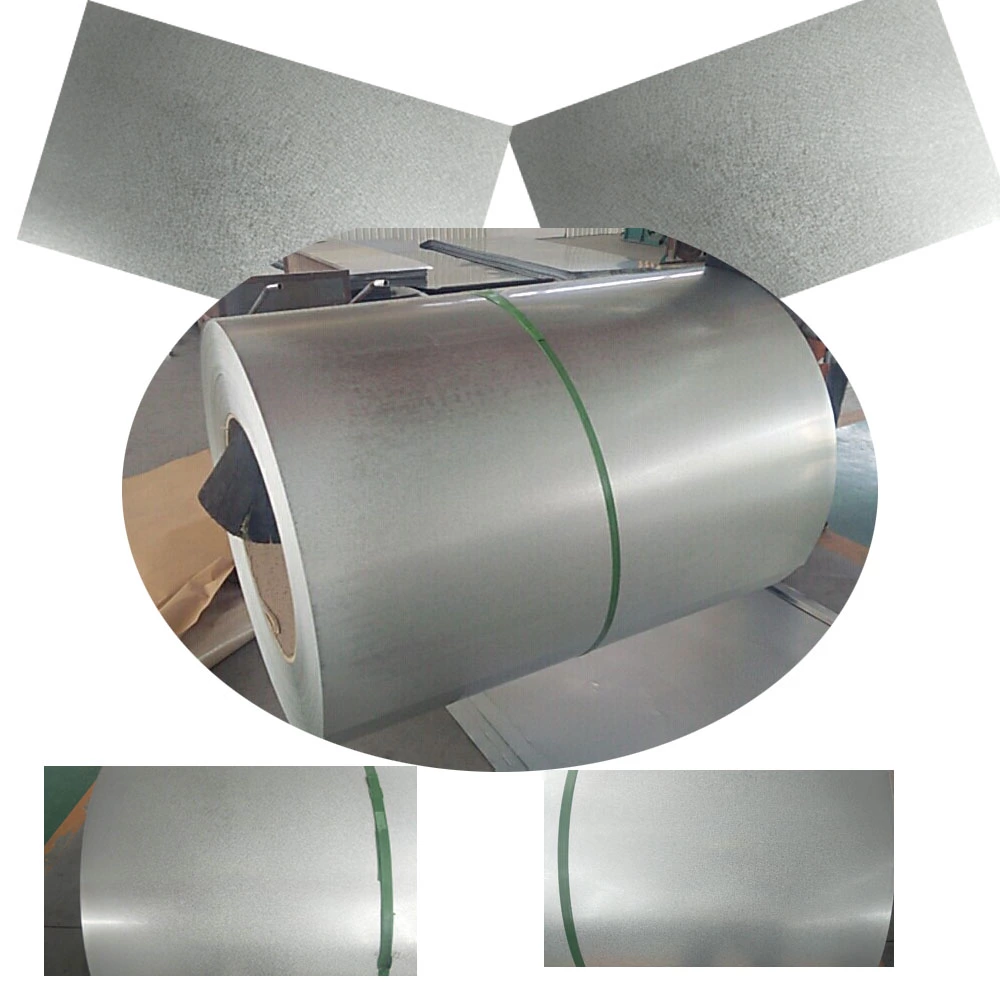

dip galvanized

Dip galvanizing is a sophisticated metal coating process that provides exceptional corrosion protection by immersing steel or iron components in molten zinc. This process, operating at approximately 840°F (449°C), creates a metallurgically bonded coating that consists of multiple zinc-iron alloy layers topped with a pure zinc outer layer. The resulting coating provides superior protection against rust and corrosion, typically lasting 50 years or more in many environments. During the process, the molten zinc reacts with the steel surface, forming a series of zinc-iron alloy layers that are actually harder than the base steel. This creates a robust protective barrier that not only shields the metal from corrosive elements but also provides mechanical protection against impacts and abrasion. The coating penetrates all surfaces, including hard-to-reach areas, ensuring complete coverage even in complex geometries. This comprehensive protection makes dip galvanizing particularly valuable for structural steel applications, outdoor equipment, and marine environments where exposure to harsh conditions is constant.