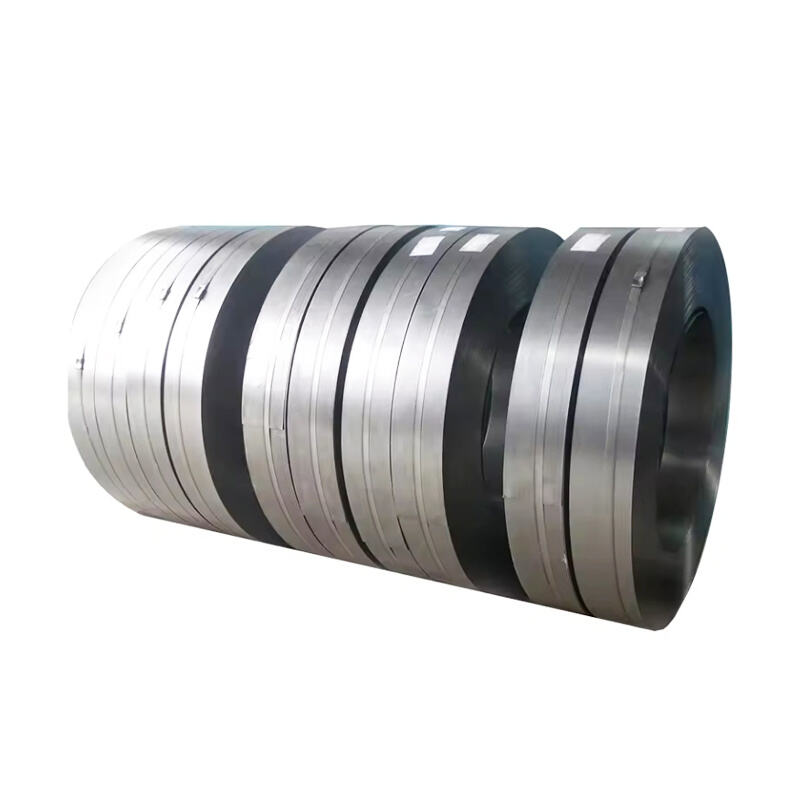

silicon steel coil

Silicon steel coil, also known as electrical steel or transformer steel, is a specialized magnetic material engineered for electromagnetic applications. This remarkable material consists of silicon-iron alloy sheets that are cold-rolled to precise specifications, typically containing 2-4% silicon content. The addition of silicon enhances the material's electrical resistance while reducing energy losses during magnetization cycles. These coils are manufactured through a sophisticated process that involves careful control of grain structure and surface coating to optimize magnetic properties. The material's unique crystallographic texture allows for efficient magnetic flux conduction in specific directions, making it ideal for electromagnetic applications. Silicon steel coils come in two main varieties: grain-oriented (GO) and non-grain-oriented (NGO), each optimized for different applications. The material exhibits exceptional magnetic permeability, low core loss, and high magnetic flux density, making it essential in the production of transformers, electric motors, and generators. Its reliable performance and durability have made it a cornerstone material in the electrical and electronics industries, contributing significantly to energy efficiency in power distribution systems.