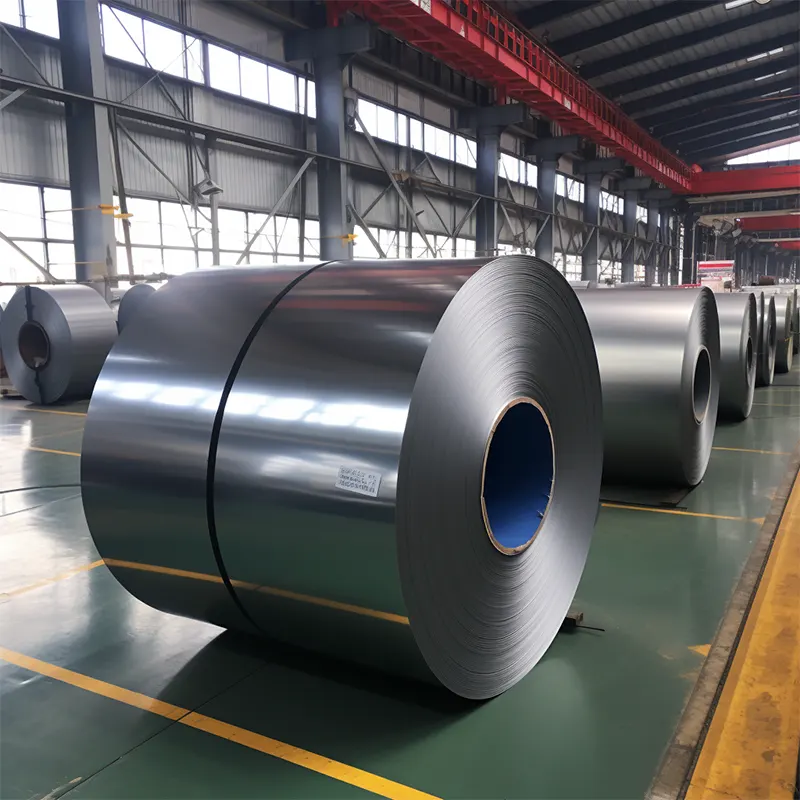

hot rolled silicon steel

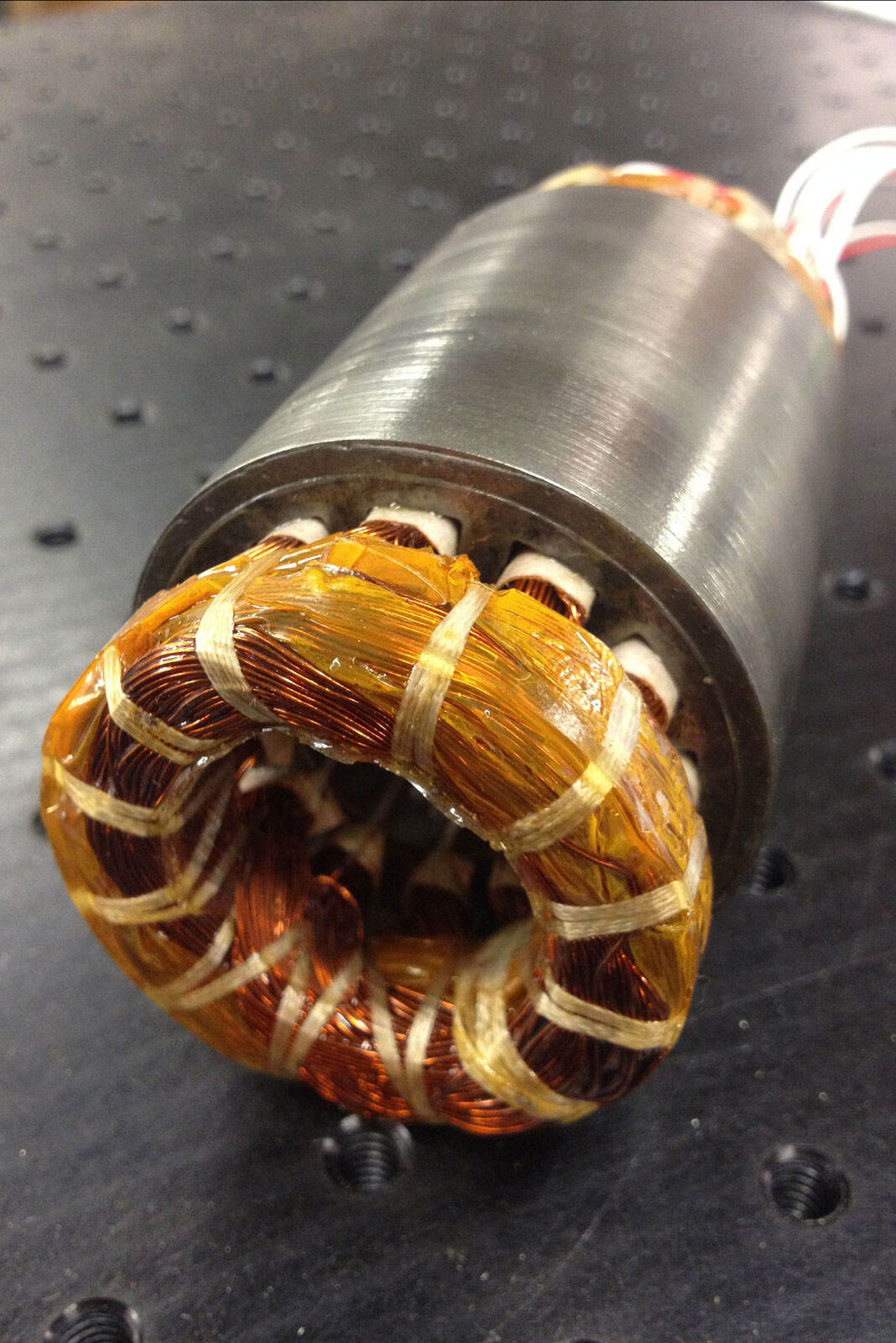

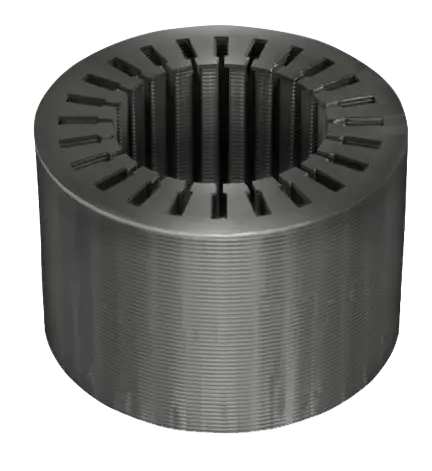

Hot rolled silicon steel represents a specialized magnetic material that plays a crucial role in modern electrical applications. This engineered material consists of iron alloyed with silicon, processed through a carefully controlled hot rolling procedure that enhances its magnetic properties. During manufacturing, the steel undergoes precise temperature control and mechanical deformation, resulting in a product with superior magnetic permeability and low core loss characteristics. The material's unique crystal structure, developed during the hot rolling process, facilitates efficient magnetic flux transfer, making it ideal for electromagnetic applications. The silicon content, typically ranging from 2% to 3.5%, helps reduce eddy current losses and improves the material's electrical resistance. Hot rolled silicon steel finds extensive application in transformers, electric motors, generators, and other electromagnetic devices where efficient energy conversion is paramount. The material's ability to maintain stable performance under varying magnetic fields and temperatures makes it indispensable in power generation and distribution systems. Modern manufacturing techniques ensure consistent quality and precise thickness control, typically ranging from 0.35mm to 0.50mm, meeting diverse industrial requirements.