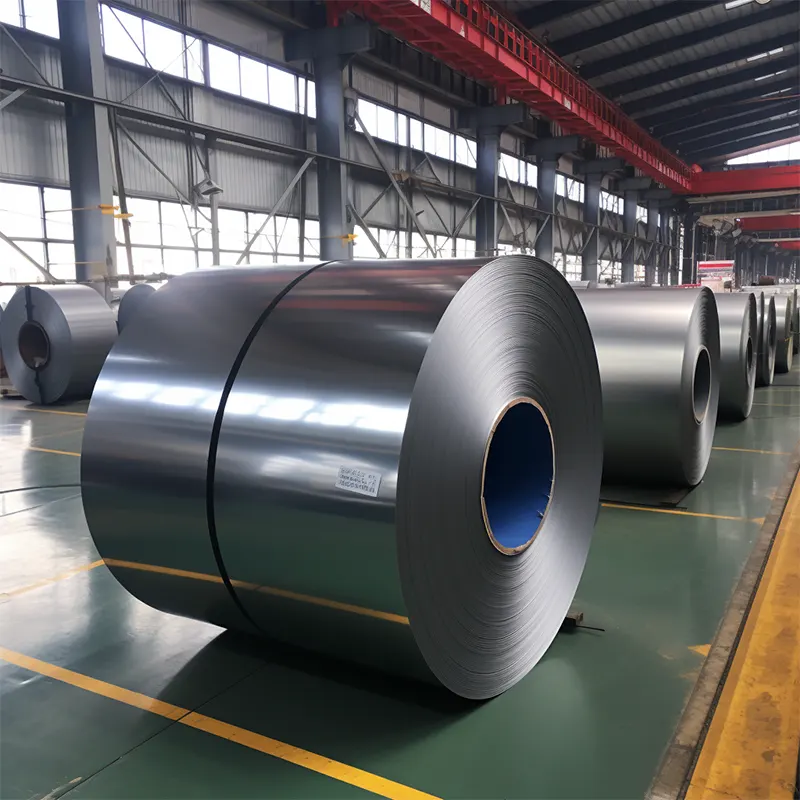

silicon steel sheet price

Silicon steel sheet pricing represents a crucial factor in the electrical steel market, directly impacting various industries that rely on this essential material. These specialized steel sheets, containing around 3-4% silicon content, are engineered specifically for electromagnetic applications. The price of silicon steel sheets fluctuates based on several factors, including raw material costs, manufacturing processes, grade quality, and market demand. Premium grades, particularly grain-oriented silicon steel sheets used in transformer cores, command higher prices due to their superior magnetic properties and lower core losses. The pricing structure typically varies according to thickness, ranging from 0.2mm to 0.5mm, with thinner sheets generally costing more due to the complex rolling process required. Current market trends show that silicon steel sheet prices are influenced by global supply chain dynamics, energy costs, and the growing demand from renewable energy sectors. Manufacturers often offer different price points for various grades, including non-oriented and grain-oriented varieties, each suited to specific applications such as motors, generators, and transformers. The price per ton can vary significantly based on factors such as order quantity, grade specifications, and geographical location of both supplier and buyer.