hot rolled steel bar

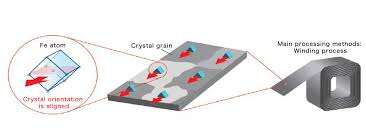

Hot rolled steel bar is a fundamental metal product manufactured through a high-temperature rolling process, typically performed at temperatures exceeding 1700°F. During production, steel billets are heated to their recrystallization temperature and passed through a series of rollers, which gradually shape and reduce the material to desired dimensions. This process not only shapes the steel but also improves its strength and internal structure. The resulting product features a characteristic dark, scaly surface finish and slightly rounded edges, making it ideal for various industrial applications. Hot rolled steel bars come in various shapes, including round, square, flat, and hexagonal profiles, offering versatility in application. These bars are widely used in construction, manufacturing, and infrastructure projects, serving as essential components in structural supports, machinery parts, and automotive components. The process enables the production of larger steel sections more economically than cold rolling, while maintaining excellent mechanical properties such as ductility and toughness. Hot rolled steel bars also demonstrate superior machinability and weldability, making them suitable for further processing and fabrication.