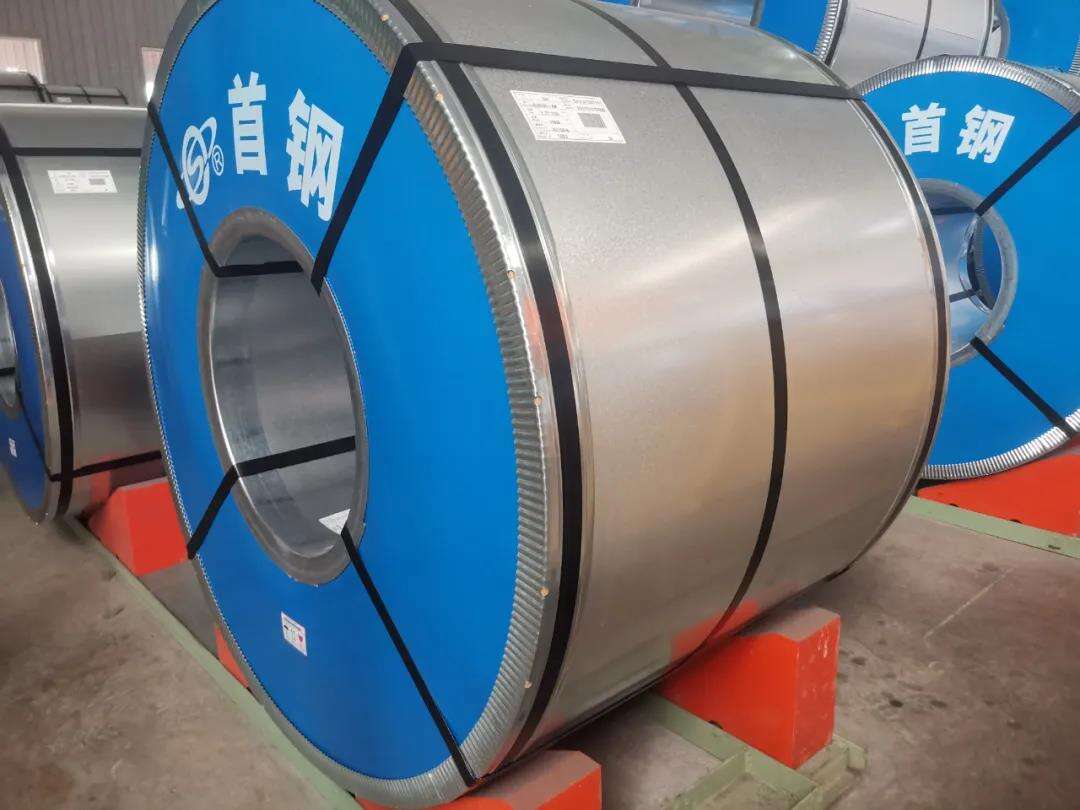

שכבת גלvanיזציה חמה

שכבת ג'לvanיזציה בטיפול חם היא תהליך מתקדם להגנה על מתכת, המשלב טבילה של רכיבי פליז או ברזל בزنק מותך בטמפרטורות של כ-450 מעלות צלזיוס (840 מעלות פרנהייט). במהלך התהליך נוצרת אינטראקציה מתלורגית בין הזנק למתכת הבסיס, תוך היווצרות שכבות של סגולי זنك-ברזל המספקות הגנה מרשימה מפני קורוזיה. עובי השכבה נע לרוב בין 85-125 מיקרון (3.5 עד 5 מיל), תלוי בתרכובת הפליז וההכנה של פני השטח. השכבה המגינה ממלאה מספר תפקודים: היא פועלת כמחסום פיזי מול לחות וchemicalים, מספקת הגנה קתודית כאשר הזנק מקריב את עצמו כדי להגן על הפליז שמתחת, וכן מציעה קיימנות רבה עם דרישות מזעריות לתפעול שוטף. התהליך יעיל במיוחד להגנה על צורות מורכבות ואזורים קשים להשגה, מאחר שהزنק המותך זורם לכל פני השטח, פינות, קצוות וחלקים שקועים. הדפוס המובהה האופייני של השכבה אינה רק מוסיפה ערך אסתטי, אלא גם מציינת הדבקה ומכסה מספקים. שיטת ההגנה היציבה והגמישה משמשת בתחומי הבנייה, תשתיות, חקלאות, העברת חשמל, תחבורה ועוד, כאשר הגנה ממושכת מפני קורוזיה היא חיונית לשמירה על שלמות מבנית ובטיחות.