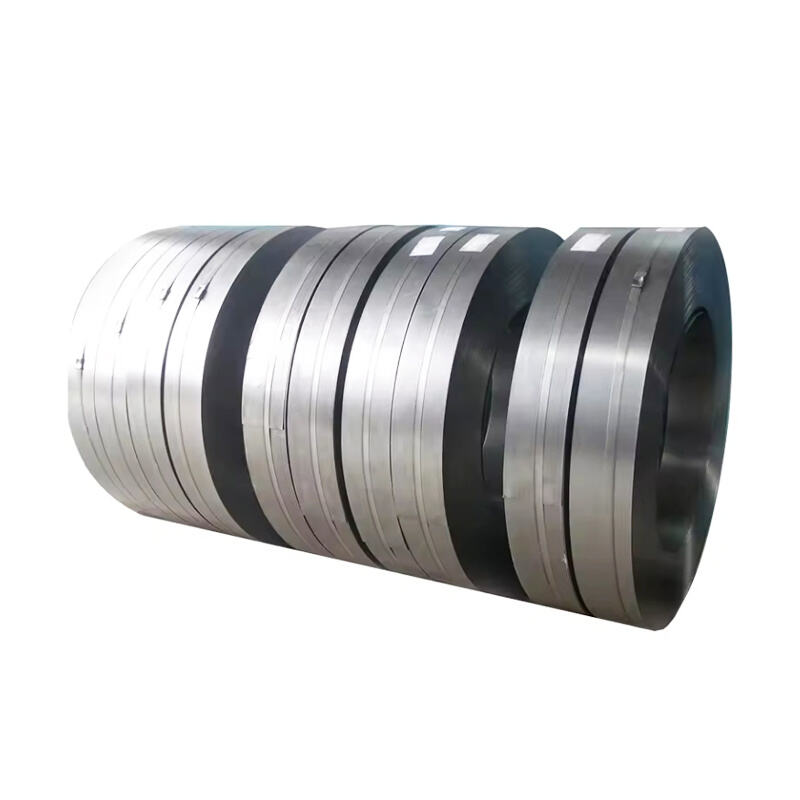

hot dipped galvanized steel coils

Hot dipped galvanized steel coils represent a premier steel product manufactured through an advanced metallurgical process where steel sheets are immersed in molten zinc. This sophisticated coating procedure creates a metallurgically bonded zinc layer that provides superior corrosion protection. The process involves cleaning the steel surface, followed by immersion in a bath of molten zinc at temperatures around 860°F (460°C). The resulting zinc coating forms multiple layers, including a pure zinc outer layer and several zinc-iron alloy layers, which contribute to the material's exceptional durability. These coils find extensive applications across various industries, from construction and automotive to infrastructure and manufacturing. The coating thickness can be precisely controlled to meet specific requirements, typically ranging from 20 to 100 microns. Hot dipped galvanized steel coils offer excellent formability, weldability, and paintability, making them versatile for diverse applications. They demonstrate remarkable resistance to atmospheric corrosion, mechanical damage, and harsh environmental conditions, ensuring long-term performance and reliability.