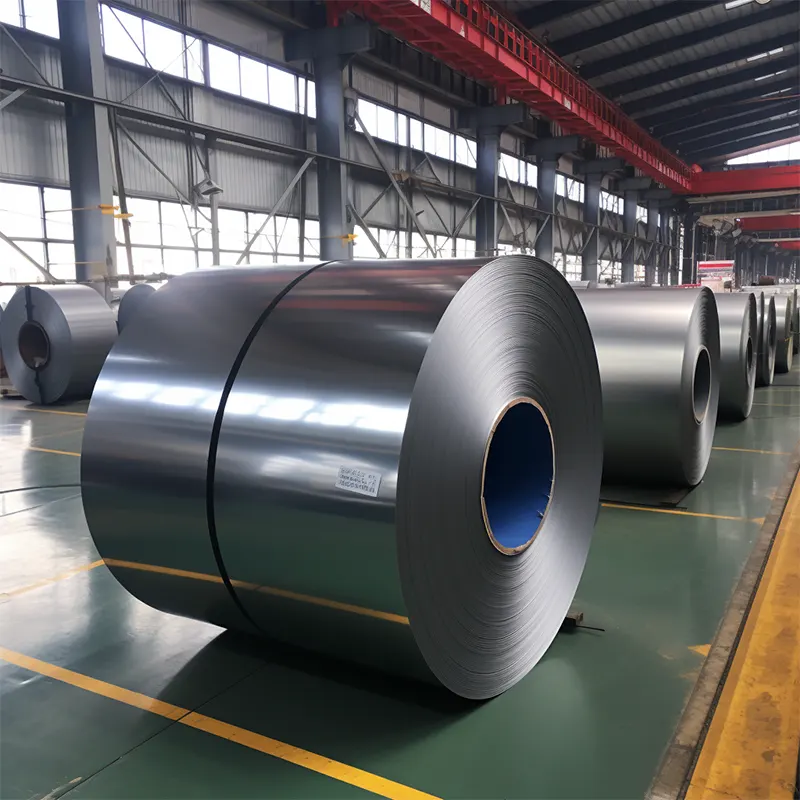

si steel

Silicon steel, also known as electrical steel or transformer steel, represents a specialized magnetic material engineered with precise silicon content to enhance electromagnetic properties. This remarkable material typically contains around 3-4% silicon alloyed with iron, creating a composition that significantly reduces core losses and increases magnetic permeability. The manufacturing process involves careful control of grain orientation and surface treatments, resulting in either grain-oriented or non-oriented variants. Si steel's unique crystalline structure allows for efficient magnetic flux paths, making it indispensable in electrical applications. The material exhibits excellent magnetic properties, including low coercivity and high magnetic saturation, while maintaining minimal energy losses during magnetization cycles. Modern production techniques ensure consistent quality through advanced rolling processes, precise thermal treatments, and sophisticated coating applications. These materials find extensive use in transformers, electric motors, generators, and various electromagnetic devices where efficient energy conversion is paramount. The continued development of si steel grades has led to improvements in core loss reduction, enhanced permeability, and better overall performance in electrical applications, making it a cornerstone material in the electrical and electronics industry.