silicon manganese steel

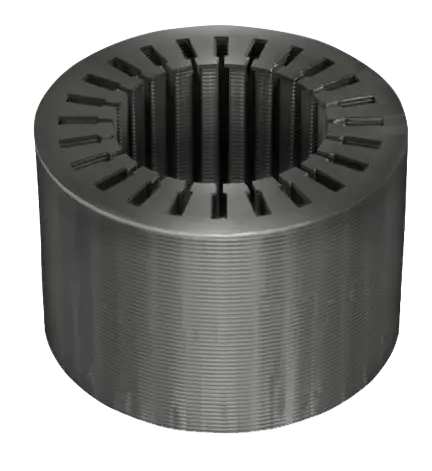

Silicon manganese steel is a specialized alloy that combines the strength-enhancing properties of manganese with the improved hardenability provided by silicon. This innovative material typically contains 0.7-1.2% carbon, 0.5-2.0% silicon, and 11-14% manganese, creating a unique combination that delivers exceptional performance in demanding applications. The high manganese content enables the material to work-harden significantly when subjected to impact or pressure, while the silicon addition improves the steel's yield strength and oxidation resistance. This remarkable alloy exhibits exceptional wear resistance, outstanding toughness, and superior work-hardening capabilities, making it particularly valuable in high-impact and high-stress applications. The material's unique composition allows it to maintain its structural integrity even under severe conditions, while its work-hardening characteristics actually cause the surface to become harder with use. In industrial applications, silicon manganese steel has become indispensable for manufacturing critical components such as crusher parts, railroad tracks, mining equipment, and heavy machinery components. The material's ability to withstand extreme conditions while maintaining its structural properties has made it a preferred choice in industries where reliability and durability are paramount.